Series 1 Version 8, 2 Winding Digital SG CIRCUIT ASSEMBLY

Analogous Series 1, Version 6 Simplified Circuit Photo

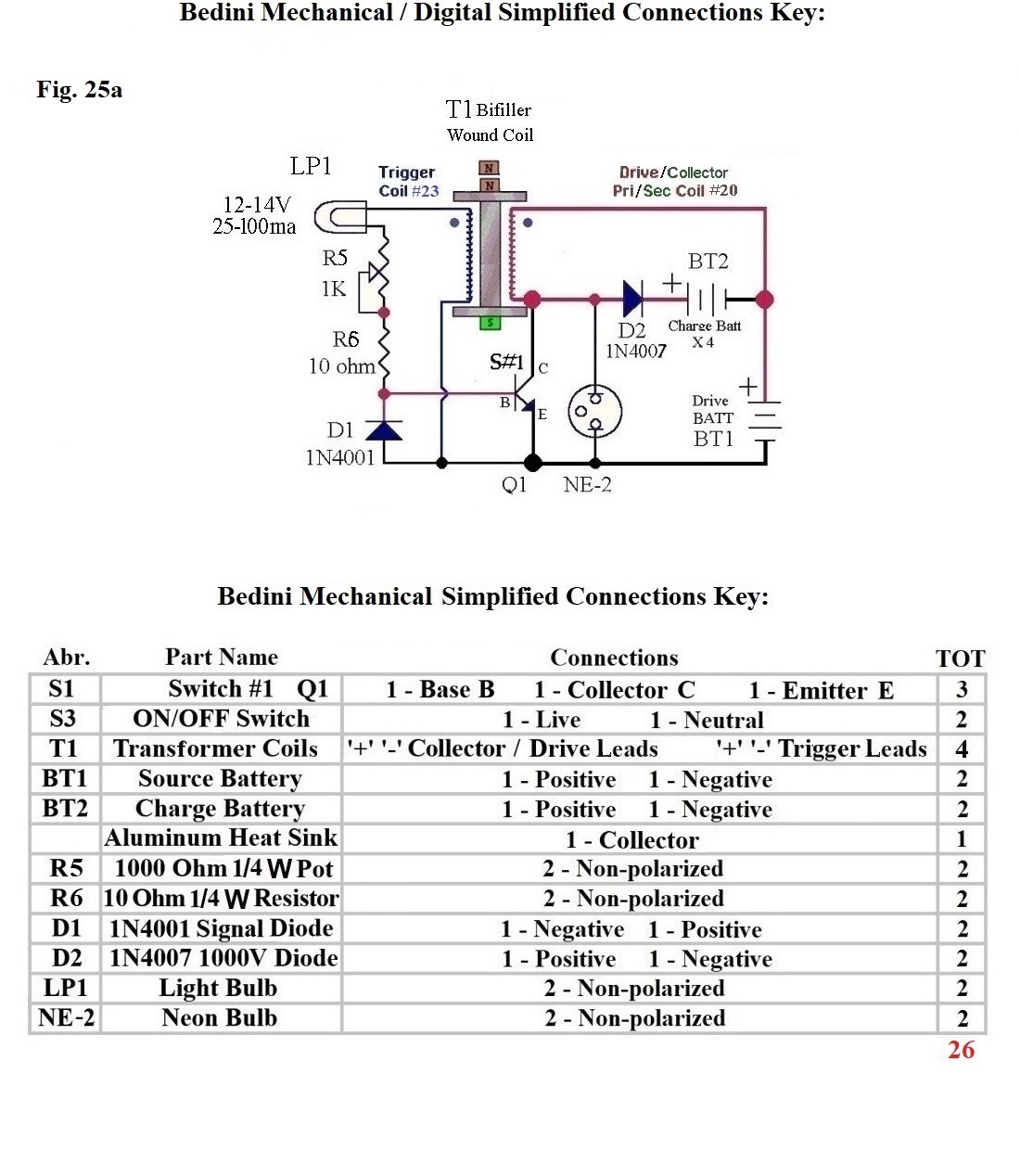

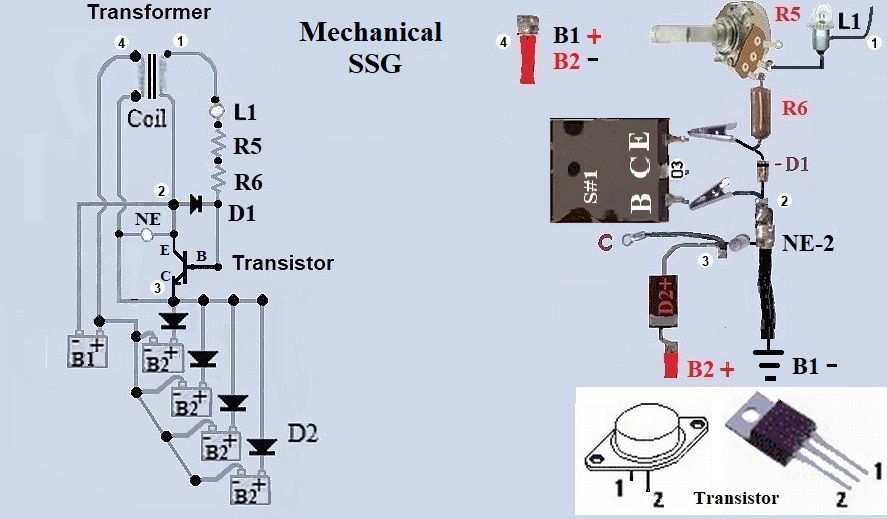

See the Bedini_Monopole (or School Girl) Schematic

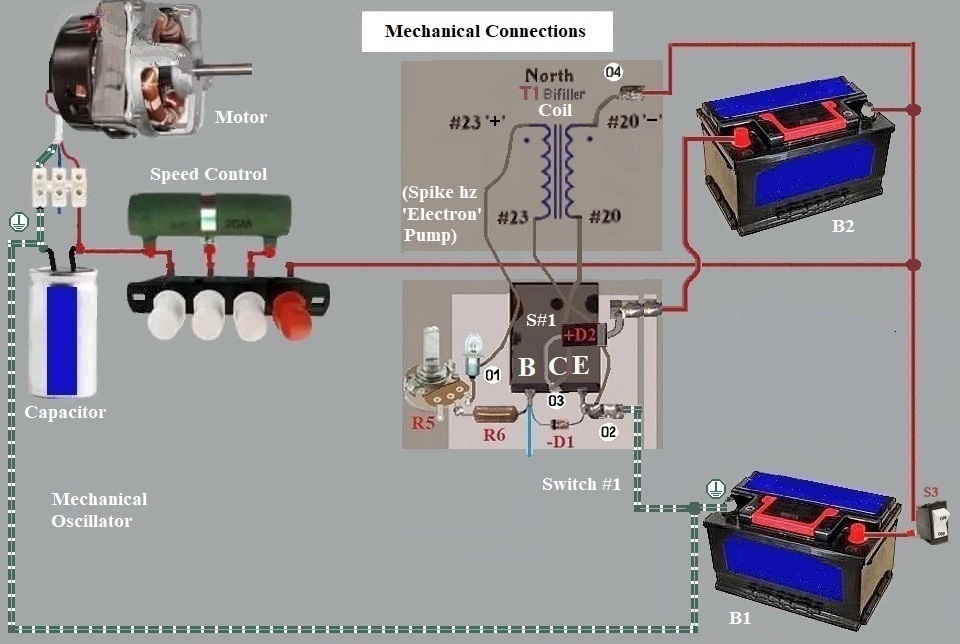

Photo of Series 1, Version 6 above corresponds to the Mechanical Schematic below

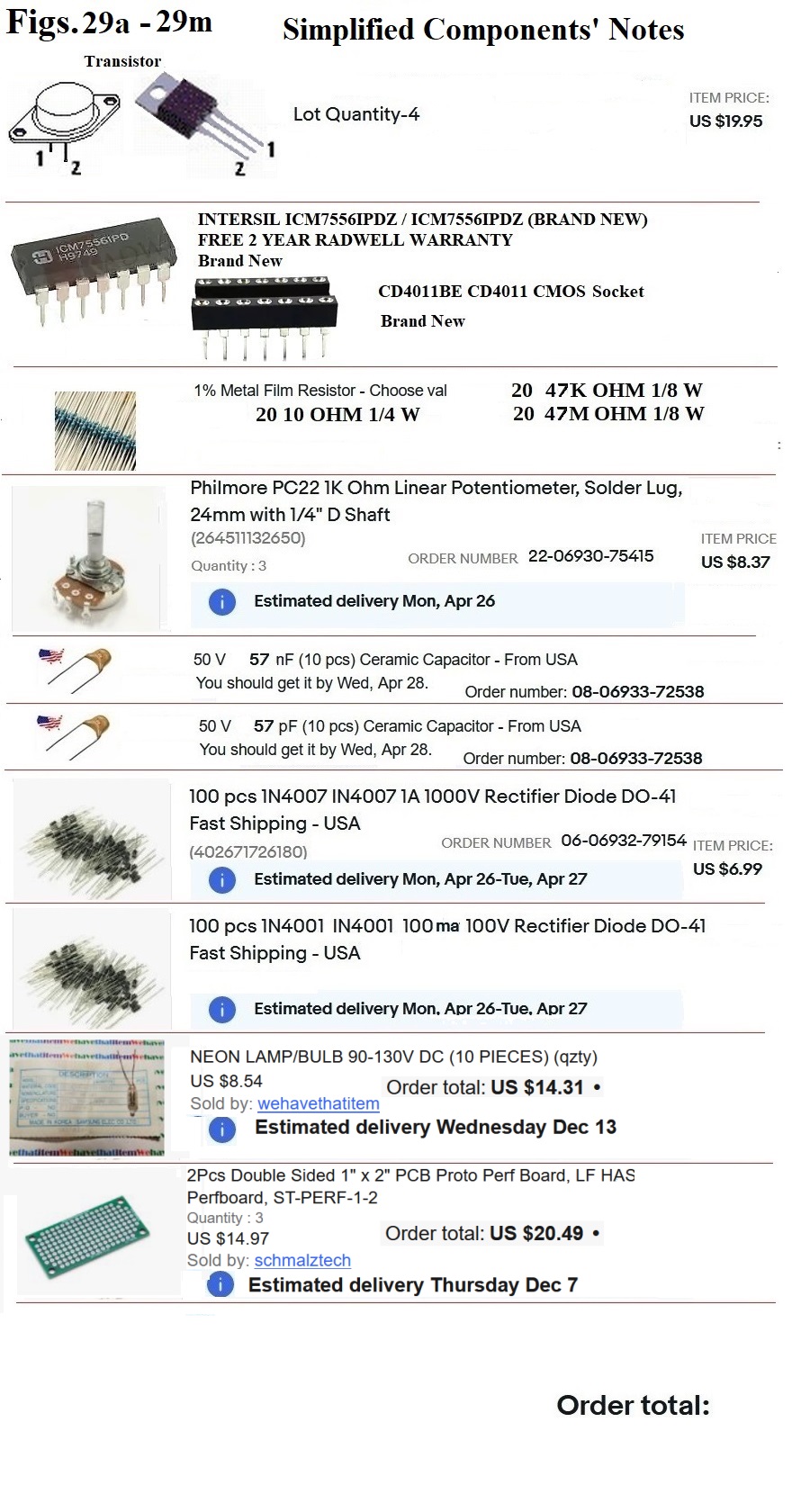

It is of particular Note that neither the components' chart or the Mechanical schematic above include an R7 between 555B's Pin 3 and the Transistor's Base (or Pin 1). The builder must here recognize that the Transistor Bedini uses for Switch #1 cannot handle more than 7 Volts at the Base. So R7 accommodates the maximum Voltage the Transistor's Base will accept if the Voltage to 555B is greater than 7 Volts The Mechanical version does not generate more than 7 Volts and, therefore, does mot require an R7.

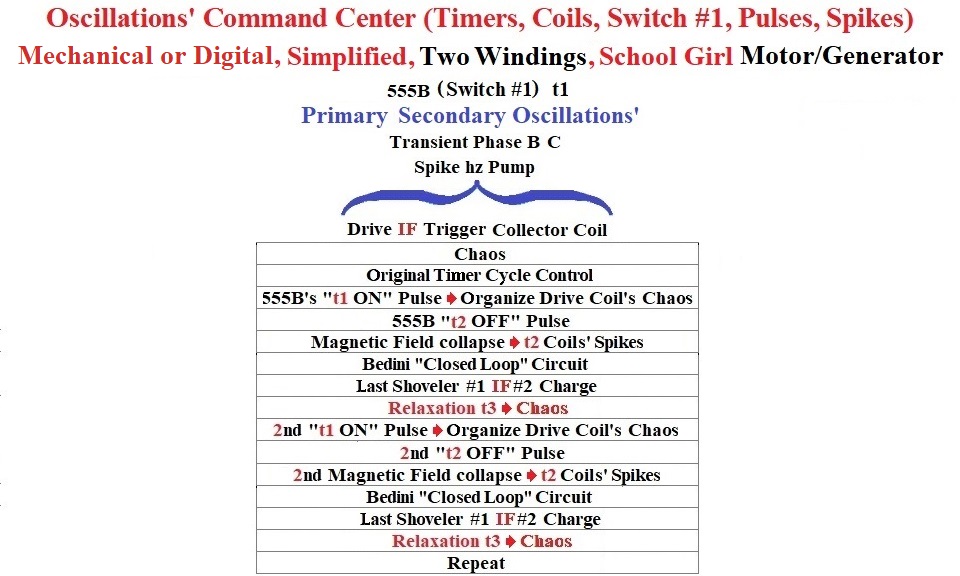

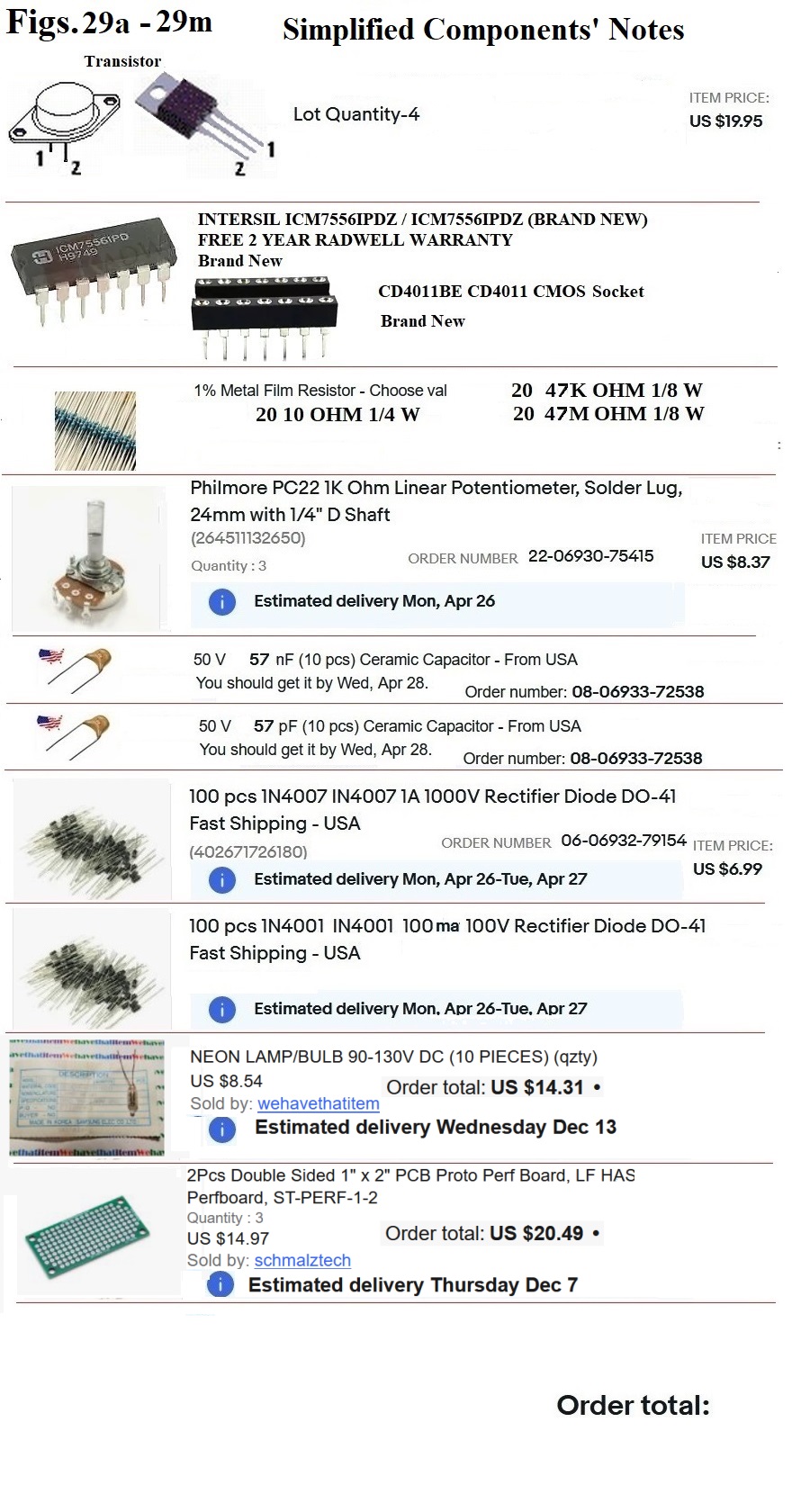

A Simplified Series 1, Version 6 of What Is Now Known Oscillation's Chart

The “Series 1, Version 6 Building A Simplified Oscillation's Chart” depicts a general visual for the characteristic design of Bedini's Simplified sequential stages, which can create more Efficient increases in an Electron Density Intensity Energy manifest as Spikes, and still isolate and capture those more Efficient Electron Density Intensity Energy increases.

Assembling Series 1, Version 6, A Simplified Two Winding Mechanical SG Circuit Instructions

Don't

overheat your Diodes, Resistors, or Transistor when soldering.

John

keeps the Wires in his Circuit as short as possible, going nearly to

the quick when fastening his Diodes to the Transistor. The Energizer

Circuit is more Efficient with shorter Wires (less R).

If

you don't know how to solder. use nuts/bolts to secure your

connections.

A 9-V Battery can be used to verify Circuit

functions before soldering the connections if Alligator clips are

used to both connect and hold components in place until you verify

function.

Use heavy gauge Wires when connecting your

Batteries in parallel or series. (less R is more Efficient).

More on Assembling the Series 1, Version 6, Simplified SG Schematic

junction

{01} is located at the Trigger Coil's North

Pole #23 Wire

Connect junction

{01}, the Trigger

Coil's North Pole #23 Wire to the

neutral side of S3 (ON/OFF Switch).

Then, also connect another

insulated #23 Wire to the same neutral side of S3 (ON/OFF Switch),

and connect this Wire to LP1,

and, after a break, connect

another Wire to the other end of LP1,

and connect this Wire to

R5 (the 1000 Ohm Pot),

and, after a break, connect the other

end of R5 (the 1000 Ohm Pot) to R6 (the 10 Ohm Resistor),

and,

after a break, connect the other end of R6 (the 10 Ohm Resistor) to

Q1's pin #1 (2N3584-1 the Base of Switch #1),

and also connect

D1's negative '-' lead (the 1N4001 Diode) to Q1's pin #1 (2N3584-1

the Base of Switch #1),

and, after a break, connect another

insulated #23 Wire to D1's positive '+' lead (the 1N4001 Diode),

and

connect this Wire to Ground.

junction {02} is

located at the Trigger Coil's South Pole #23

Wire, and is the BT1's negative '-' lead

(Source Battery or Ground)

Connect junction {02} the

Trigger Coil's South Pole #23 Wire to

another insulated #23 Wire,

and also connect this Wire to Q1's

pin #1 (2N3584-1 the Emitter of Switch #1),

and also connect

this Wire to D1's positive '+' lead (the 1N4001 Diode).

and

also connect this Wire to NE-2.

Then, after a break, connect an

insulated #26 Wire to the same neutral side of S3 (ON/OFF Switch),

and connect this Wire to 555B's

pin #8

and also connect this Wire

to 555B's pin

#4.

Then, also connect one lead of R1B

(the first 47 K Timing Resistor) to

555B's pin

#4,

and, after a break, connect the other end of R1B

(the first 47 K Timing Resistor) to

555B's pin

#7.

Then, also connect R2B (the

second 47 K Timing Resistor) to 555B's

pin #7,

and, after a break, connect the other end of R2B

(the second 47 K Timing Resistor) to

555B's pin

#2,

and, also connect C1B (the

56 nf Timing Capacitor) to 555B's pin

#2,

and, after a break, connect the other end of C1B

(the 56 nf Timing Capacitor) to 555B's

pin #1,

and also connect another

insulated #26 Wire to 555B's pin

#1,

and connect this Wire to Ground.

Then, after a break,

connect an insulated #26 Wire to 555B's

pin #3,

and connect this #26 Wire

to Q1's pin #1 (2N3584-1 the Base of Switch #1),

and, after a

break, connect another insulated #26 Wire to the other side of R7

(the 330 Resistor),

and connect this Wire to H11D1 pin #1,

and, after a break, connect another insulated #26 Wire to H11D1

pin #2,

and connect this Wire to Ground.

junction

{03} is located at the Drive/Collector Coil's

South Pole #20 Wire

Connect

junction {03}, the Drive/Collector

Coil's South Pole #20 Wire to an

insulated #20 Wire,

and also connect this Wire to NE-2,

and

also connect this Wire to a D2's '+' (the 1N4007 Diode's positive '+'

lead),

and, after a break, connect D2's negative '-' lead (the

1N4007 Diode) to BT2's positive '+' lead (the Charge Battery).

junction {04} is located at

the Drive/Collector Coil's North Pole

#20 Wire

Connect junction

{04}, the Drive/Collector

Coil's North Pole #20 Wire to an

insulated #20 Wire,

and connect this Wire to BT2's negative '-'

lead (the Charge Battery),

and also the neutral side of S3 (the

ON/OFF switch),

and, after a break, connect another insulated

#20 Wire to the live side of S3 (the ON/OFF switch),

and

connect this Wire to BT1's positive '+' lead (the Source Battery),

Copper

Winding Wires

Aluminum Heat Sink

Series 1 Version 6, 2 Winding Mechanical SG CIRCUIT ASSEMBLY

Series 1 Version 8, 2 Winding Digital SG Digital CIRCUIT ASSEMBLY

Either any of my Transient Phase Simulations or the CircuitMaker Program are using Excel

(or Spreadsheet type techniques) for their intense calculations.

It is, therefore, advisable and wise to know Three things:

Any of these resources files can be corrupted if your

computer's resources are over-taxed.

and a requirement to use any of the Transient Phase Simulations is to have Excel or an equivalent.

Preserve Original File, and Work only from a backup to avoid File corruption when using these resources, and be vigilant protecting your work.

(or Spreadsheet type techniques) for their intense calculations.

It is, therefore, advisable and wise to know Three things:

Any of these resources files can be corrupted if your computer's resources are over-taxed.

and a requirement to use any of the Transient Phase Simulations is to have Excel or an equivalent.

Preserve Original File, and Work only from a backup to avoid File corruption when using these resources, and be vigilant protecting your work.