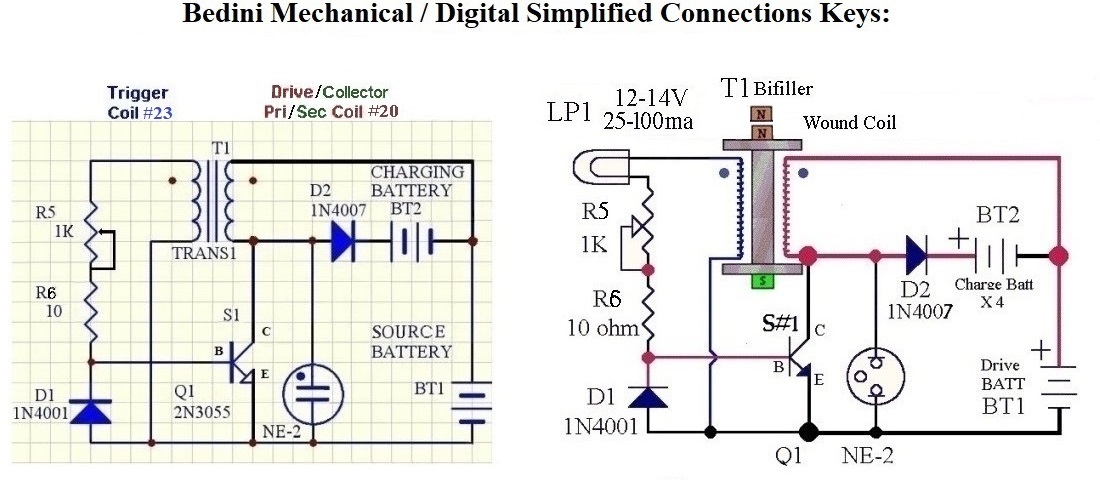

Series 3 Version 7, 2 Winding Digital SG CIRCUIT ASSEMBLY

Series 3 Version 8, 2 Winding Digital SG CIRCUIT ASSEMBLY

Bedini's

focus has always been “Creating Original "Ot" Timed”

Mechanical or 555B's Switch #1 ON Pulses in

the Primary Oscillations' Command Center “as

collapsing Magnetic Fields are allowed to organize”

the shorted Coil's Electron chaos

into “a Higher Electron Energy

Density Intensity”, which is

presented in each Coils' Winding as a VL

Spike (see Figs. 23a, 23b and Coil

Saturation), with Transient Phase B's Spike hz Pump's

555B's Timed Switch #1's

“t2 OFF Pulses” in the Primary

Oscillations' Command Center, then “isolating”

each Coils' individual VL

Spike (that was created by Mechanical or

555B's Timed Switch #1's “t2 OFF Pulses”), “returning”

each Trigger and/or Drive Coils' VL Spike

to the Main Source and

“storing” (or accumulating in

a Capacitor) each Collector Coil's Timed Switch #1's “t2

OFF” VL Spike;

the Bedini Circuit capitalizes on the

Magnetic Field's collapse by injecting an extra,

Circuit Resonant VL

Spike, doubling the Energy produced

in each cycle's expansions and collapses, and

“the Energy accumulated from these two series of VL

Spikes are then delivered from pile C”,

during the Secondary Oscillations' Command Center's Transient Phase

C's 555A Timed t3 Pulse, to

not only Charge the Battery Bank with pile C (accumulation

stored in the Capacitor), but also

end both Transient Phase C and this

Ot cycle's series of Transient Phases, to then repeat the

entire series of Efficient Phases with another Ot cycle at the

Resonant frequency.

Building

What Is Now Simply Known means the Bedini design has been streamlined

and Simplified with both greater Energy Efficiencies and

a higher output potential. My

Transient Phase Simulation accentuates all past and present

Efficiencies in its analysis as you refine each component's

contribution. The Feedback for an

additional t1 Pulse was added, and

another up-scaled design eliminated the need for the Storage

Capacitor, Diode Bridge

and an independent Collector Coil, and

the second Wave Timer along with its components for the Pressure

Relief Valve are also no longer needed.

The remaining components demonstrate the necessities

required to comprehend and explore the features discovered by Tesla.

ALL these features,

characteristics and combinations are readily available

in the Transient Phase Simulation, and

accelerate any serious Fiddlers wildest anticipations of

comprehension and success.

In An Analogy to Summarize the Process in

A Simplified School Girl Events

(Transient Phase Simulation Spreadsheet #1)

In

summary of the One Dimensional process, envision

an individual hired for each Transient Phase's Output Voltage Stage, beginning with every Coil Winding, and ending with the Output Diodes in your Simplified North Pole Generator, every individual with

their own shovel, and each individual's shovel has a

specific size designed for their particular amount of Timed work. These individuals each perform their repetitive task of moving an increasing volume of Electrons (through

the Circuit's design) by Transferring

the VL Spike's Electron Density increases to the next Stage for further processing. These individuals represent the

dynamic design of Tesla's intent to create the higher

Average Density of Electrons required to replace the

Source Volt's Electrons being dissipated or consumed to

power the load. COIL

WINDING SPOOL Specifications

WINDING

THE COILS Label

each Coil's Wire to eliminate error and confusion. BATTERIES,

RECHARGEABLE

Obtain

the Battery manufacturer's data sheets (from the internet).

The following characteristic profile curves are important: Voltage,

Current, Charge capacity and Discharge Capacity.

Your

goal is a sufficient and Higher AVE DC The

Transient Phase Simulation offers all

these highlighted Blue Reference

features. OPERATING

PROCEDURES

The

Neon Bulb, NE-2, provides a safe path for the Energizer's output

Energy in case the receiving Battery is disconnected while the motor

is running. This prevents burn-out of the Transistor. This light

should not go on unless the Charging Battery is disconnected. Once

the Energizer is configured for optimum operation, connect a fully

charged Source Battery and at least one equal size fully discharged

Charging Battery in the Energy output Bank. Let the Energizer run

until the Source Battery reaches the manufacturer specified minimum

discharge voltage. Measure the Charging Battery capacity by fully

discharging it (to manufacturer's minimum voltage) into a known load.

Compare the Charging Battery Bank capacity to that of the Source

Battery. RAMIFICATIONS

The

worst Battery in the set does not become the weak link in the chain.

CONCLUSION

A

successful replication of the basic Bedini SSG is only the beginning

of the learning process. The next step is to

upgrade to more advanced setups involving all the characteristics

included with My Transient Phase Simulation (multi-strand Coils,

multiple stators, higher frequencies, etc.... Applying this

technology to other fields such as fuel cells is also a possibility.

REFERENCES

The First Shoveler is in Output Voltage Stage #1 for a Series 3 Circuit. The Trigger Coil is where the One Dimensional VL Spike creation (or origination) begins with a half cycle's t1 Pulse. It should be noted that the First Primary Shoveler at the Trigger Coil delivers the First half cycle's t1 Pulse in the "Switch #1's ON Pulse" and Transfers the VL Spike to the Drive/Collector Coil to be processed when the Trigger Coil's Field collapses at t1's Switch #1's OFF Pulse.

The Second Shoveler is in Output Voltage Stage #2 for a Series 3 Circuit. The Drive/Collector Coil is where the One Dimensional VL Spike is directed to be enhanced, (by the Diode Process), which began with a t1's half cycle's Pulse. It should be noted that when the VL Spike in the Drive/Collector Coil collapses, another half cycle's t1 Pulse is generated in the Trigger Coil to create a Second VL Spike in the Drive/Collector Coil. The Second Shoveler is performing double duty, as another VL Spike is then Transfered to the Drive/Collector Coil to be processed when the Trigger Coil's Second Field also collapses at t1's Switch #1's OFF Pulse.

The Third Shoveler is in Output Voltage Stage #3 for a Series 3 Circuit. Diode #3 is where the One Dimensional VL Spikes are enhanced and are then each moved in the Two half cycle Pulse sequencea to the Output Battery Voltage Charging Stage during t2's half cycle's Pulse.

Guidelines for constructing

A Simplified School Girl

(Transient Phase Simulation Spreadsheet #1)

Plastic, 3" diam. by 3" long, with an open, 3/4"

Core.

Tolerance

Core

needs to be +/- 20%. Length of spool can be +/- 40%. Material needs

to be low Reluctance, non-metallic, non-Magnetic, and adequately

sturdy. These Tolerances are unique from the School Girl

Motor/Generator. My Transient Phase Simulation gives an intense

insight to how the attributes of Inductance affect VL

Spikes.

Coil's Electromagnet Core

Coil's

Electromagnet core material to propel Magnets along as the

Electromagnetic core is pulsed by each Magnet of the Wheel and also

the extra Feedback Pulse Circuit.

Welding Rod

0.042" diameter copper coated steel rod. 3 foot lengths.

(will be cut to the length of the Coil's core. Get 3-5 lbs. (around

10 rods of 3 feet each).

Rough cut is okay. Diameter is

not crucial, and could be smaller by 50% or larger by 100%. Available

at your local welding supply store (such as Oxyarc) or hardware store

(such as True Value or Ace or an auto parts store). Estimated Price

$0.60 per rod. The thicker the rod, the harder it is to cut. You're

going to be cutting a lot to fill the spool's core.

Filling

The Coil's Electromagnet Core

Be sure the

rods in the Coil's end that will be facing the Magnets, are flush so

your Magnets' Wheel spins without hitting either a core's rod or the

spool

If you drill a 1" hole in the core's base about

1/2" deep, you don't have to cut your rods shorter.

Use

glue on each rod to fill the spaces and keep them from moving.

Tap

the last few rods in with some light object until no more rods fit.

Wind the Coil's two Wires on the spool together.

It is very

important that the Coil's two Wires be next to each other the entire

distance of the winding.

Fill the spool. Approximately

450 to 900 Turns.

You may use a drill to spin the spool.

A variable speed drill offers more control, making it easier to count

Turns and ensure the two Wires are wound parallel the whole distance.

John says the exact number of Coil Turns is not crucial

to operational success. Close is adequate. Symmetrical windings are

not crucial. Think fishing or kite spool.

The Circuit's window of winding tolerance is very wide. However, an

exact count and Wires' lengths will be necessary for scientific rigor

in documenting, calculating, analyzing and

reproducing precise results.

One

additional update on the Coil (T1). Cut 150 to 350 feet of

each wire (same length). You can use two #18 size wires at 150 feet

instead. Instead of winding two wires in parallel, twist the two

wires like Litz wires. For the smaller size wires you can have 6 or

more twists per inch. Don't twist too much or they will break. Then

wind it as you would have any other wires.. . Use the parts listed.

You can use Transistor #1 BD243C, as found in John's patent, in place

of the one listed.

Counting visually is nerve-wracking

and prone to error. Use an audible trigger in winding (e.g. a clacker

on the spool). Alternatively, you might affix tape to both ends of

the spool, protruding outward around 1/2". This tape will hit

your hand as the spool rotates, helping you count Turns.

The

powering Source of the Energizer Circuit Motor/Generator, and

Batteries receiving a Charge from the Circuit (Source and output need

to be different Batteries; closed loop will not work).

Battery

Specifications

6 to 24 volt

Batteries are functional, however, At least two 12-volt lead acid

Batteries are recommended. One for Source, one for Charging. More are

recommended for experimental options.

Tolerance

The

Battery's voltage rating is not crucial, and can be in the range of 6

to 24 volts for this particular Energizer Circuit/Motor Generator

design. Bedini recommends getting 10 new or used Interstate 6v golf

cart Batteries and make 5 12v batteries. However, Source and Charging

Batteries need to be matched in their voltage and impedance (size).

There can be more than one Charging Battery on the receiving end,

connected in parallel, if each Charging Battery matches the voltage

and impedance (size) of the Source. For your first replication, use

new Batteries to eliminate (minimize) reasons for Circuit

malfunction. Not all rechargeables are suitable for receiving

this type of Charge. Lead acid recommended.

One 1N4007 to Each Battery

in the Charging Bank

Dec. 9, 2004

http://groups.yahoo.com/group/Bedini_SG/message/431 Peter and John

recommend that we set up our 1:4 Battery arrangement according to the

following:

Isolate each

Source matching Battery in the Charging Bank

In

addition to the 1N4007 Diode coming from the Circuit to the first

Charging Battery's positive terminal, branch off to each Charging

Battery with a 1N4007 Diode so that each Charging Battery is seen

independently. (Once again, a lower Resistance). Note Harlan

tried omitting the Diode coming from the Circuit, just using one

going to each Battery, and that did not work.

You may

branch out your Charging Circuit from D2's Positive connection with

either a single D2 Diode to each Charging Battery, or you can

parallel one or more identical D2 Diodes for each Charging Branch.

Just make sure all paralleling D2 Diodes polarities are correct (to

make one big Diode for each Branch). If using 5 Diodes per 4 Battery

Charging Branch in a 5 Battery Charging setup (1 powering Battery and

4 Charging Batteries) you will have 5 x 4 = 20 D2 Diodes total. Hint,

D2's in parallel, and parallel Charging branches both have

independent effects of lowering Resistance.

Battery

Care

It is important to know your

Battery manufacturer's optimal operating parameters so you do not

inflict damage by Charging or discharging them too fast or too

high/low. You will not need to worry about speed or level of Charging

while using the Bedini Simplified School Girl Circuit. But if you use

another Charging apparatus, you need to know your Batteries'

characteristics and Charging parameters. If your Source and

Charging Batteries are matched in voltage rating and impedance (size)

the Circuit inherently balances the Charging rate to a level that is

not only safe, but even beneficial to

the Charging Batteries. Overcharge with

the Simplified Bedini School Girl Circuit is not nearly the concern

it is with other chargers. Batteries

charged with the Bedini Simplified School Girl Circuit actually

perform better under frequent use than letting a few idle days pass.

When your Charging Battery is identical to your Source

Battery, this is a Control.

(1) This Control allows you to test

the discharge parameters of a Battery, independent of the Circuit and

under the same discharge parameters.

(2) Additional Batteries

of the same voltage and impedance can be added to the output in

parallel.

(This ratio scenario graphically demonstrates there

can be more Energy put out than the Source has put in).

(3)

This same Energy ratio can be the widest and most crucial variable in

the Energizer system.

....A Higher AVE

DC requires either more and/or Higher VL

Spikes

........More

Drive/Collector Coil Inductance tenders Higher VL

Spikes and, therefore, a

Higher AVE DC

............Increase

B8, (see Wire AWG, Wire's

density)

............Increase B9,

(# Wires' / Winding (see Wire AWG, Wire's

density)

............Increase

Source's Voltage, K32, (see R8

and AMPs R12)

............Increase

E4, Core's Diameter (see surface

area)

............Decrease E5,

Coil's Height (see AWG, Wire's density)

............#

Drive/Collector Coil's TURNS

................Decrease

E8, Drive/Collector Coil's Turns (see

AMPs R12)

................Increase

E8, # Drive/Collector Coil's Turns (see

AWG, Wire's density)

............Increase

F28, # Drive/Collector Coils, (see Wire

AWG, Wire's density and VL Spike's Hz)

............Two

Drive/Collector Coil Windings K23,

amplifies Spikes

............Individually

wrapped Wires K24, may require more

Drive Coil Turns

............Exponential

Wires K26, Theory on # Wires Inductive

Reactance amplification

........Less

Time (t1, t2) precipitates a Higher VL

Spike Frequency

............Increasing

K25, K31,

Lowers Transistor response Time, (less t1)

............Decreasing

R1B, B35, Timer,

(less t1)

................Decreasing

R1B, (1K), relative to R2B,

(270K), balances the Duty Cycle (t1, t2)

............Decreasing

R2B, B36,

Timer, (less t1, t2)

............Decreasing

C1B, B38,

Timer, (less t1, t2)

............555

R2B Bypass Diode ON, D37,

Timer, (less t1, t2)

............Feedback

Diode ON, K27, Can double the frequency

of the Spike hz Pump VL Spikes, or more

Plan

the entire experiment before purchasing components. My Transient

Phase Simulation was designed to assist Tinkerers in every way

imagineable, and it is very useful.

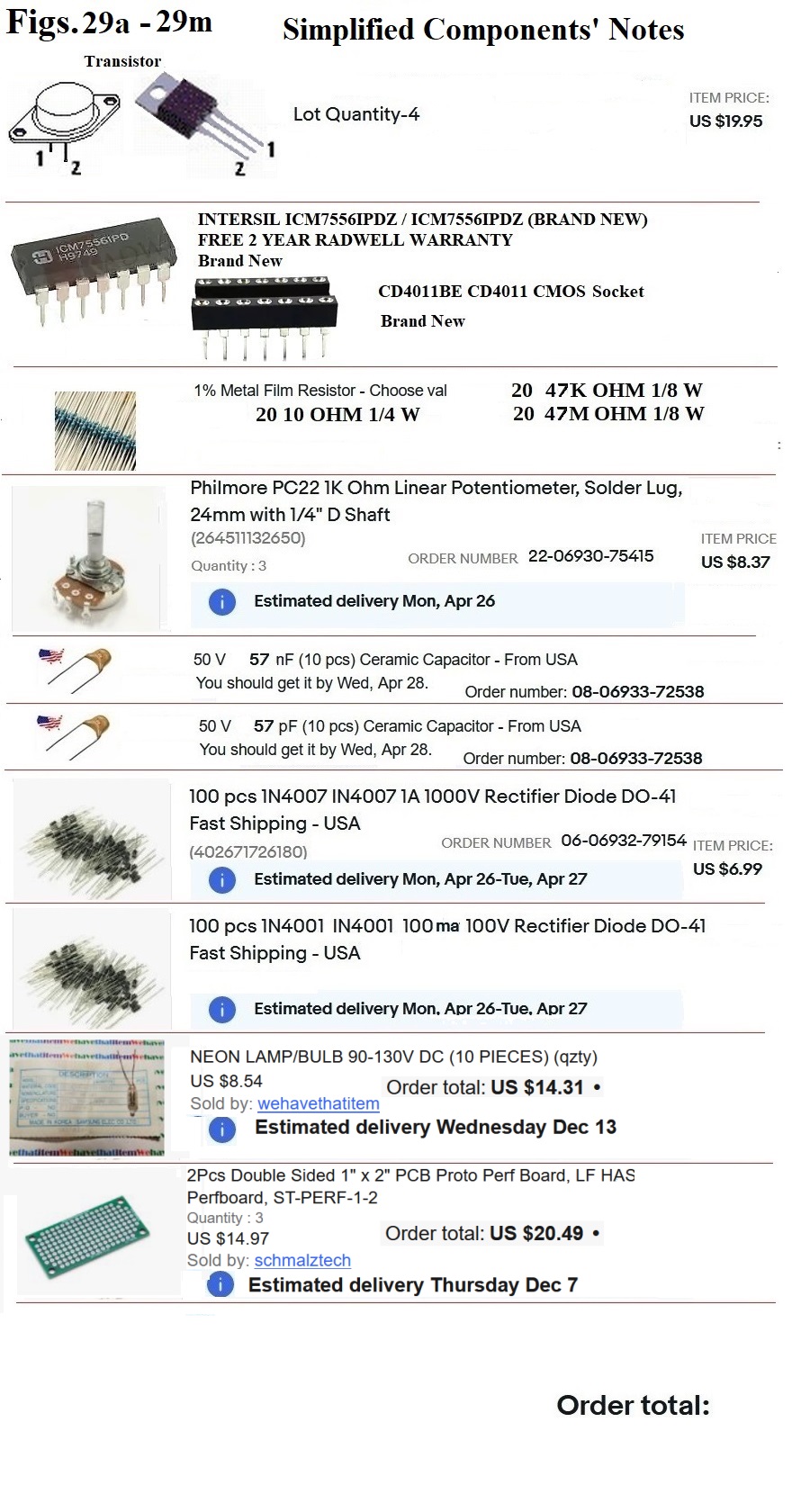

Neon

Bulb (NE-2) Specifications

Chicago Miniature Neon Base

Wire Terminal T-2 65VAC .6mA NE-2, One, 90-Volt DC Neon Bulb. A1A by

Chicago Miniature See also Lumex P/N GT-NE3S1025T, lumex.com

http://www.lumex.com/product.asp?id=1000657 .

CAUTIONS

Dangers

associated with this project are mainly with the Batteries, but

soldering and Wheel rotation are also considerations. Be sure you

understand the risks and take necessary precautions.

While

this design can deliver some good shocks, the

shocks with these specific component values are not,

generally, of a

dangerous level.

This device

/ Energizer Circuit should not be operated without a receptacle for

the Energy (e.g. Charging Battery). The

Neon Bulb (NE-2) is protective and

cautionary, and does not light up under

normal conditions. If the Neon Bulb is not in place, the

Transistor is likely to be burned out by the VL

Spikes. The Neon Bulb absorbs the

transient Energy like a shock absorber (or a necessary defuser

that is neither "tripped" or needs to be reset).

Over

Unity Evaluation

Evaluate your Energizer's performance

for Over Unity after Charging discharged Batteries from a fully

Charged Battery, and analyze the ratio for the amount of Energy

extracted from the Source Battery with the amount of Energy in the

Charged Battery.

Operating the

Motor / Generator

To run the Motor / Generator, connect

the Energizer Circuit to the Source and give the rotor a spin (by

hand or some other external mechanical force). It will then

accelerate or decelerate to a point of equilibrium. At some

Resistances in the Circuit, there will be more than one stable rate

of rotation.

Tuning the Motor /

Generator

Tune Circuit / Motor to its lowest current /

highest RPM sweet spot (or Resonance) by adjusting the Pot from its

lowest value, up till the additional pulses start to flicker LP1 and

Drive Current increases, then back off a little. till the extra

pulses stop, and let the RPMs stabilize before any more tweaking is

done. When the extra Feedback pulses show, LP1 will flash.

The

Circuit needs a sufficient Wattage Potentiometer (or Pot). Pick ma

size of LP1 that will not allow additional Feedback pulses when the

Pot is at its lowest value (because of LP1's Resistance), but not so

high a Resistance that LP1 will not allow a flickering Feedback near

the motor's sweet spot of Resonance.

With the Energizer

running, adjust the Base (see Transistor #1's Feedback Pulse @ R5)

Resistance for minimum Source current draw and VL Spikes'

(AVE DC) voltage. It is important that Motor / Generator Circuit

operation is sustainable at your component's values.

PERFORMANCE

EVALUATION and TIPS

In functional application, you should not draw

power from a Battery that is presently being Charged. You should have

one Bank of Charge Batteries, and one Source Battery for discharge,

and switch them.

Performance

Once

you have confirmed your Energizing system is functional, beef

up your connections to lower Resistances and optimize Efficiency.

Use a heavy gauge wire and terminal connectors with crimping. The

above photo shows a set-up for rotation of Batteries from the back to

the front, allowing for single Battery Charging (fresh from the

front) while that Battery comes up to the same voltage as the rest of

the Charging Bank, so they can then be connected in parallel.

TUNING (or Adjusting Resistance to

find Resonance)

Note that the

arrangement includes a switch to enable meter readings without

extended disconnection of the Circuit. Depending

on how responsive the meter is, the Circuit is interrupted for

maybe one or two seconds using this method.

The 25 Ohm

Resistors give a fine-tuning capability. The bread board enables hard

Resistor plug-in for the range desired. The 5k Ohm Pot enables a wide

berth of tuning. Note: the 5k ohm Pot tends to

be unstable at holding a Resistance. If you wish to lock into

a particular Resistance, you should consider inserting a desired R,

bypassing the 5K Pot.

No need to stop the Circuit when rotating Batteries.

No

need to have the Bank standing idle, discharging while the Battery

from the Source comes up to charge.

When the Source

Battery discharges, the Battery with the highest charge from the Bank

(not necessarily the one that has been there the longest), can be

brought to the front to run the Circuit NB.

Either any of my Transient Phase Simulations or the CircuitMaker Program are using Excel

(or Spreadsheet type techniques) for their intense calculations.

It is, therefore, advisable and wise to know Three things:

Any of these resources files can be corrupted if your

computer's resources are over-taxed.

and a requirement to use any of the Transient Phase Simulations is to have Excel or an equivalent.

Preserve Original File, and Work only from a backup to avoid File corruption when using these resources, and be vigilant protecting your work.